Track Testing StopTech Big Brake Kits

by Dave Zeckhausen

As part of their development process, StopTech fine tunes each brake kit design by taking it to the track and, if necessary, adjusting that design before it goes to market. I was invited to participate in a full day of track testing with StopTech in December, 2002. This article is my "diary" of that day. After a day of track testing and 3 days at the production facility in Torrance, California, I have a much better understanding and appreciation for the engineering and testing that goes into making StopTech big brake kits work so well.

StopTech's Balanced Brake System Philosophy

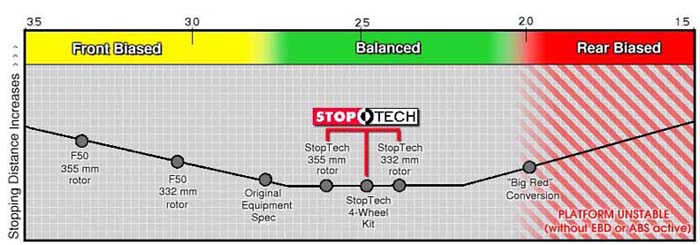

StopTech places tremendous emphasis on the concept of a balanced brake system. While they have several patents related to rotor cooling and caliper stiffness, what sets StopTech apart from other big brake companies is their dedication to preserving the factory balance. As the chart below indicates, a brake kit with too much rear bias not only results in longer stopping distances, but is unstable without the assistance of electronic stabilization control or ABS. I can relate to this with my road race car which has an adjustable proportioning valve. The handling gets pretty scary when I've got too much hydraulic pressure going to the rear brakes.

Stopping distance vs. front/rear brake bias (Audi S4 data)

If the brakes are too front biased, the front tires tend to saturate prematurely and the stopping distances become longer, both with and without ABS. ABS does not fix improper bias. StopTech controls the bias of their kits by retaining the stock master cylinder and juggling caliper piston and rotor sizes to come up with optimum brake torque balance.

An Audi S4 kit was used to generate the numbers for the chart above. StopTech makes 3 different kits for the S4, all of which are better balanced than even the factory brakes. According to the chart, an Audi S4 kit using F50 calipers and 355mm diameter rotors would be front biased, due to the larger piston sizes used in that caliper. The same calipers with smaller 332mm rotors produces the counterintuitive result of shorter stopping distances than the kit with bigger rotors! A Porsche "Big Red" conversion that uses adapter brackets to attach Porsche 993TT front and rear calipers and rotors to the Audi S4 is rear biased and, not only has a longer stopping distance, but might even be unstable if ABS is disabled.

By careful selection of caliper piston sizes and exhaustive track testing (as you'll see below), StopTech has the potential to yield the shortest stopping distances of any aftermarket brake kit, combined with safe and stable handling.

I flew out to California from New Jersey late Tuesday night, December 10th, arriving around midnight. I was picked up at my hotel the next day at 6:30 AM by Ilja Burkoff, the StopTech test driver, and we drove for over an hour to a former military airstrip in Camarillo that StopTech had rented for the day. Two Nissan 350Z sports cars, a silver Performance model and a copper Track model were waiting for us. A third car would arrive late in the afternoon for the 355mm front and 4-wheel brake kit testing.

The Nissan 350Z test cars

The first order of business was to set up the test area. Matt Weiss, StopTech's Customer Service Manager, spent nearly an hour with a gas powered leaf blower, cleaning off the braking zone. Other folks laid out cones to mark the braking zones and skid pad area. A radar gun was set up on a tripod and a cover fitted to prevent aircraft radar reflections from interfering with our test data. The radar was interfaced to a laptop running custom software that calculated and plotted stopping distances and produced tables with all sorts of information.

Steve Ruiz setting up the radar gun and laptop

The support van was filled with tools, brake rotors, and calipers. There were three different kits to be tested this day, including a 332mm front, 355mm front, and a 4-wheel kit. In addition, we needed to test the stock brakes on the Performance and the Track models in order to have a baseline for comparison. All the tests (except the 4-wheel brake upgrade) were to be conducted using the same tire make and model in the same size and on the same size wheels. We had a long day ahead of us!

The van loaded with tools and brakes

Steve Ruiz, StopTech's Co-Founder and Engineering Manager, suspected the factory Brembo brakes had never been properly broken in, so he used that as an opportunity to spend some quality time with me (zooming to 100 mph, then standing on the brakes - over and over again) while casually explaining all the tests we would be running and how the data would be collected. Frankly, I think he was just trying to see how many g's I could take before throwing up. Fortunately, I don't get motion sick, but I now have a better appreciation for what my customers go through when I take them along to bed in their new brakes.

Steve was correct about the factory brakes not being bedded in. They went into green fade and then, after cooling off, felt much stronger than when we first tried them out. Now we could run a fair comparison test.

350Z Track Model with Brembo brakes

Nissan 350Z Track Model Brakes

Our first goal was to fully characterize the factory brakes. So we started our testing with the Nissan 350Z "track model." Ilja would drive to the end of the runway and then turn around and head straight for the radar station at about 64 mph. When he reached the last of three cones, he would apply the brakes fully, allowing ABS to activate. The laptop started collecting data before the stop was initiated and kept on collecting data after the car was stopped. Steve used the mouse to "lasso" the data on the graph from 60mph to 0mph and discard the rest. This left us with a plotted graph that showed how the car performed during the 60mph to 0 portion of the stop. It's pretty much a straight line. This technique is more accurate than relying on the driver to try to go exactly 60 mph and then stomp the brakes. It also eliminates the differences between runs where the driver may hit the brakes more quickly on one run than another. Many magazines test brakes this way, although some use the less accurate and less repeatable method of relying on the driver to gauge when he's going 60 mph. It's important, when comparing tests, to know how the data was collected.

We ran the car through ten back-to-back stops from 60 mph. Each time the car stopped, we measured and the rotor temperatures and then sent the car around for another pass. After five or six passes, the rotor temperatures stabilized. The front rotors reached 565 °F and the rear rotors reached 370 °F. We did a total of 10 stops from 60mph and the temperatures varied by about +/- 10 °F, but it was clear that we could keep this up all day and they wouldn't get any hotter. The average stopping distance was 117.3 feet.

Measuring rotor temperatures after an 80 mph stop

Next, we ran through six stops from 80 mph, collecting the same data. The front rotors stabilized at 590 °F and the rear at 400 °F. Average stopping distance was 208.7 feet. And finally, we did four stops from 100 mph. It was somewhat disconcerting to see the car heading straight for us at that speed, but there wasn't a hint of fade from the Brembo brakes on the 350Z Track model. The final rotor temperatures were 721 °F in front and 477 °F in the rear and the stopping distances averaged 328.3 feet.

Stopping the 350Z Track Model from 100 mph

The next phase of the test is to determine how the brakes interact with ABS and the stability control system. We ran a "Modified J-Turn" test, which is used by engineers who design ABS systems. A skid pad is laid out with cones and very carefully measured calibration points are marked with dots of paint. Then, the car is driven around the skid pad to find the maximum speed it can navigate the constant radius turn. The 350Z managed to reach 46.5 mph.

Locking up the brakes in the Modified J-Turn Test

Next, the driver makes a run at the skid pad at 46.5mph. Partway through the turn, he locks up the brakes and the car comes to a stop. A tape measure is then laid out between the calibrated dots nearest where the car stopped. Then, a measurement is taken from each wheel to that tape with the measurement taken along the line of sight from the wheel to a calibrated reference point. The distance from wheel to tape is recorded, as is the distances from the dots, and this is all entered into a laptop. Car wheelbase and track is also entered. The laptop does some crunching of numbers and comes up with the "departure angle" of the car from the intended direction. If it is outside of a narrow range, the brake system needs to be rebalanced with either larger or smaller pistons in the front or rear calipers.

Preparing to measure points for Departure Angle calculation

Of course, the factory Brembo system on the 350Z Track model passed the J-Turn test, as was expected. The results did show the brakes to be somewhat front biased.

The final test for the Track Model was to disable the ABS system and conduct a high speed stop to see if the front or rear brakes locked up prematurely. This test was completed without incident and confirmed the front bias detected by the J-Turn test.

Nissan 350Z Performance Model Brakes

Now it was time to test the 350Z Performance Model, which comes from Nissan with single-piston, floating calipers and much smaller rotors. We were all very interested to see how the two factory cars would compare. After ten stops from 60mph, the front rotor temperature stabilized at around 700 °F, 135 degrees higher than the track model. The rear rotor temperatures reached 478 °F, which was 108 degrees higher than the Track model. The average stopping distance was 118.0 feet, which was less than one foot longer than the Track model. Very interesting. We figured the difference would become more significant at higher speeds, so we pressed on.

Stopping the 350Z Performance Model from 80 mph

After six stops from 80mph, and then four stops from 100 mph, the front rotors reached 804 °F and the stopping distances began to increase as fade set in. I began to wonder which way to dive if the car couldn't stop, but figured the test driver would expect us to stay still and would swerve around us. I kicked myself for not asking about this before we started! Stopping distances from 80mph and 100mph averaged 210.5 and 333.6 feet respectively. That's within 5 feet at 100 mph and within 2 feet from 80 mph of the 350Z Track Model's performance. The Brembo brakes didn't seem to make a significant difference on stopping performance until the cars started doing repeated 100mph stops, at which point the increased thermal capacity of the bigger rotors kept brake fade at bay, while the Performance model with smaller brakes began to experience fade.

The J-Turn test and the ABS-disabled test went without incident.

The fraternal twins cooling down after the initial brake tests

Now the real work was about to begin. It was time to test the StopTech 332mm and 355mm front brake kits But first the cars needed to cool down a bit.

Preparing for the brake installations

While the cars cooled, we pulled out the ramps, tools, and brake kits to prepare for some field installations. I took this opportunity to wolf down some spicy chicken drumsticks that Ilja had in his cooler. My jet-lagged stomach was telling me it was time for lunch, even though it was still mid morning.

The pit crew goes to work on the 350Z Track model

Since the silver car was still too hot to work on, we decided to take a closer look at the Brembo brakes on the 350Z Track model.

A close-up of the Track model's factory Brembo set-up

We pulled the wheels off and took some measurements. The 350Z Track model comes with 324mm x 30mm front rotors and 322mm x 22mm rear rotors. So, despite the hype, the rotors on that car aren't as massive as I had expected. Even the smaller of the two StopTech front brake kits we were about to test was significantly larger at 332mm x 32mm.

Even more shocking is the price of replacement Nissan rotors for the 350Z track model. Front rotors (p/n 40206-CD000) are $519 each and rear rotors (p/n 43206-CD000) are $494 each from the local Nissan parts counter. Ouch! In comparison, the non-Track Nissan 350Z rotors are $111 each for both front and rear.

Now it's the Silver 350Z Performance model's turn. Stock brakes shown

StopTech 332mm Front Big Brake Kit

After we put the 350Z Track model back together, it was time to install the first brake kit on the silver 350Z Performance model. I rolled up my sleeves to help and did most of the installation on one side while someone else worked on the other.

While removing parts, I measured the rotors. The front rotor was only 296mm x 24mm and the rear was 292mm x 16mm. That is a skinny rear rotor! I don't think the Performance model will stand up to any serious track use unless the brakes are upgraded.

Mat Weiss finishes the installation while I munch on chicken drumsticks

After the StopTech 332mm front kit was installed and the brakes bled, Ilja took it out to the end of the runway and did a series of stops to bed in the new pads and rotors. After it was broken in, he cruised back and forth to let the brakes cool down. Then it was time to start with the measured brake testing again.

Measuring Rotor Temperature after 100mph Stop

As before, we did twenty stops, the first ten from 60mph, followed by six stops from 80mph and then four stops from 100mph. The difference was noticeable even at 60mph. The stops were several feet shorter than the stock brakes and the rotor temperature was 155 degrees cooler after just 10 stops. From 100mph, the car stopped 4.3 feet sooner.

Next, it was time to go back to the skid pad for the modified J-turn test. The results of that test showed the car to be within acceptable limits. The ABS-disabled test was also successful, so the kit was deemed to be market ready. Sometimes the results of the J-Turn test will mean they have to go back to the van and install a different set of calipers with slightly larger or smaller pistons. Thankfully this one was good to go on the first try. Even so, it took several hours to test.

StopTech 355mm Front Big Brake Kit

Now it was time to test the StopTech 355mm kit. The third test car had arrived with the StopTech 355mm front brakes already installed. This car also had Toyo Proxes tires and a modified suspension, so a direct comparison to the other cars is not really possible. We ran through the full set of 20 stops again and found the massive front rotors to be 268 degrees cooler than the stock rotors after the first ten stops from 60mph and the stopping distances were slightly better than the smaller StopTech kit. The slight improvement was probably due to the tires, since the balance was engineered to be the same as the smaller kit. The J-Turn tests and ABS tests were again aced on the first try.

That was two kits down and one more to go.

Cutting away the backing plate to make room for the 355mm x 32mm rear rotor

StopTech 4-Wheel Big Brake Kit Kit

The final brake kit to be tested was the 4-wheel big brake kit with 355mm rotors at all four corners. Given the undersized stock rear rotors on the 350Z, this is the kit that will need to be used by anyone who plans to seriously race this car.

Up on the jacks went the third test car again. The rear brakes were installed and the front calipers switched to ones with bigger caliper pistons. The tiny 292mm x 16mm stock rotors were replaced with much larger StopTech 355mm x 32mm rotors, requiring that the old backing plates be cut away to make room. Tin snips made short work of the backing plate trimming and the rear kit was installed. Next, the front calipers were replaced with ones that were sized to work with the StopTech rear kit They utilized larger caliper pistons. We had several sets to try and the plan had been to run through them in sequence to zero in on the optimum pair. But we were out of time, so the decision was made to gamble on the caliper with the smallest pistons in order to shift more braking to the rear.

.

Smoke rising from the front brakes (hard to see in photo)

By the time we finished installing the rear brakes, it was getting dark. We would have to conduct the braking tests with flashlights. We maneuvered all the vehicles so they illuminated the braking zone and the radar gun and made the first run from 60mph.

That first run was the best one that had been made all day. I don't have the data from that run, but I recall it was around 111 feet from 60mph. We thought we had another winner. Then things started to go downhill quickly.

Smoke rising from the rear brakes as the rotor temperature is measured

As we made a few more runs, the stopping distances increased as did the rear rotor temperatures. It was obvious that we had picked the wrong set of calipers for the front. Unfortunately, we were out of time, so we aborted the braking runs and moved over to the skid pad to conduct the J-Turn test. That test confirmed that we were too rear biased, as did the ABS test. Out of time and out of daylight, we decided to pack it in at 8:00 PM and continue the 4-wheel kit testing another day. We were exhausted after such a grueling day, but there was still work to do, picking up cones, putting away tools, and cleaning up the test area.

We stopped for dinner on the way back to the hotel and had a chance to talk about the day's testing. A tremendous amount of data had been collected and we hadn't really had a chance to absorb and process it all. I was starting to gain a deeper appreciation for the amount of work required to prepare a StopTech brake kit for market.

The following week, StopTech went back (without me) to the track and ran the full set of tests on the 350Z 4-wheel kit again, this time starting with stock bias and working their way down to the optimum piston sizing required to minimize stopping distances, yet not mess up the stability control system. Since then, the 4-wheel 350Z kit has become one of StopTech's more successful kits. The March 2004 issue of "Sport Compact Car Magazine" recorded the best stopping distance ever for a 350Z running the StopTech 4-wheel kit. That 350Z required only 98 feet to go from 60 to zero mph!

|

Performance Model |

Track Model |

StopTech 332mm |

StopTech* 355mm |

StopTech * 4-Wheel |

|

|

Front Rotor |

296mm x 24mm | 324mm x 30mm | 332mm x 32mm | 355mm x 32mm | 355mm x 32mm |

|

Rear Rotor |

292mm x 16mm | 322mm x 22mm | Stock | Stock | 355mm x 32mm |

|

Best 60-0 |

116.01 feet |

114.32 feet |

113.67 feet |

112.52 feet |

111 feet |

|

Ave. 60-0 |

118.01 feet |

117.28 feet |

115.83 feet |

115.08 feet |

N/A |

|

Best 80-0 |

207.28 feet |

204.89 feet |

203.92 feet |

204.42 feet |

N/A |

|

Ave. 80-0 |

210.47 feet |

208.72 feet |

206.74 feet |

206.56 feet |

N/A |

|

Best 100-0 |

329.97 feet |

325.35 feet |

325.63 feet |

323.51 feet |

N/A |

|

Ave. 100-0 |

333.57 feet |

328.30 feet |

326.87 feet |

326.16 feet |

N/A |

|

Temp 60mph |

706/478 °F |

553/371 °F |

551/436 °F |

438/501 °F |

N/A |

|

Temp 80mph |

705/440 °F |

571/395 °F |

554/418 °F |

421/469 °F |

N/A |

|

Temp 100mph |

804/565 °F |

721/477 °F |

695/510 °F |

594/631 °F |

N/A |

|

*Test conducted on a 3rd car with modified suspension and Toyo Proxes tires. All other tests were conducted with stock suspension and factory Bridgestone RE40 tires. There are no products available in this category.

Categories

Manufacturers

|